Sample pendant above uses Amaco Potter’s Choice Glaze – Blue Rutile PC-20 on Laguna Speckled Buff Clay.

Introduction

These are the basic steps and materials I use to make my pendants. After you have a little experience, you will adapt the method and materials to suit your work (and fashion) style. The possibilities are endless! You may see many more pictures of my pendants, buttons and earrings at this link.

Please feel free to comment below with questions, and I will get back to you as soon as possible.

Disclosure: I was not compensated for this post. I am an affiliate of Amazon, and will receive a small commission if a link on this page is used to make a purchase.

Materials

- Soft High-Fire stoneware clay (with little to no grog – I’ve used Laguna Porcelain 5, Speckled Buff, Red Calico and Greystone)

- Small clay cutters in different shapes (available at craft stores in the polymer clay and cake decorating aisles)

- Textured Objects (rubber, plaster or wooden stamps, buttons, leaves, etc.)

- Rolling Pin not used for food

- 1/8″ – 3/16″ Thickness Strips – I bought square dowels at the craft store, but I may try hardwood strips in the future

- Cornstarch (Note – this may mold in your clay bag if you have leftover clay. If this bothers you, you can skip the cornstarch.)

- Wooden ware boards (plywood square or rectangular boards)

- 1/8″ or smaller diameter drill bit

- Double Ended Pin and Carving Tool

- Kemper High Temp Wire 24 gauge (optional)

- Kiln Bead Tree or Bead Rack

- Your favorite glazes

- Jump Rings

- Jewelry Pliers & Jump Ring Opener Tool

Method

Sprinkle a wooden work area with cornstarch. Using about 1/2 pound, roll out clay using the thickness strips as a guide. As you work, sprinkle clay with a little cornstarch and turn clay over and roll on the other side occasionally, until you reach the desired thickness. Try to roll it as evenly as possible. The clay should not stick to the surface.

Using firm, steady pressure, press your textured objects into the clay. You can use the rolling pin to roll flat objects. Using the small cutters, cut out shapes and carefully move them to a wooden ware board. Try not to bend them or the pendant may permanently lose its flat shape.

Repeat as often as you like!

Jewelry Designs from Nature: Woodlands, Gardens, Sea: Art Bead Jewelry Designs Inspired by Nature

Jewelry-Making Tools & Supplies

When the pendants have dried enough that you can pick them up without squishing them, gently press down on the edges on both sides to round them slightly. Set them aside to dry to almost leather-hard.

Pendants: When the pendants are almost leather-hard, use the drill bit to gently drill a hold near the top of the pendant. Start from the front of the pendant and drill slowly towards the back. As you get the hang of this it will go quicker. Clean off the clay from the drill bit before drilling the next pendant.

Buttons: Drill 2 holes near the center of the clay shape.

No-Hole Option 1: You may use the Kemper High Temp Wire 24 gauge instead of drilling a hole. Bend 1/2″ length of wire over the thin end of a paintbrush. Use flat-head pliers to gently insert into the top of a pendant. Leave enough loop to hang on a bead tree wire.

No-Hole Option 2: Use a glue-on bail after firing. For this option, do not glaze the back of the pendant – lay it on the kiln shelf for firing instead of using the bead tree. Use E-6000 Adhesive or similar product to glue on the bail, and let cure for 48 hours (or follow package directions).

Sign the back of the pendants using a Stylus:

When the pendants are leather-hard, use the small curved scraper on the Double Ended Pin and Carving Tool to gently scrape off the excess clay from the drill hole and signature. Set aside until bone dry.

Jump Rings and Jump Ring Tools

Bisque Fire

Stack the pendants three – four high on the kiln shelves and fire to Bisque Cone 04 according to your kiln manufacturer’s instructions.

Glaze

I prefer high-fire glazes, but have successfully used both Mayco and Amaco Low-Fire(Cone 06 – 05) Glazes and Laguna and Coyote High-Fire (Cones 5 – 6) on high-fire stoneware clay. As you know, different glazes react differently on different clays. Some glazes drip too much for small object. Do some glaze testing with your favorite glazes to see how they work on the pendants.

Brush the glaze on evenly. Low-fire glazes usually need at least 3 coats. High-fire glazes vary. After the glaze has dried, use the pin end of the Double Ended Pin/Carving Tool to scrape out the glaze from the hole. This is VERY IMPORTANT. If there is too much glaze in the hole, it will stick to the bead tree wire.

Glaze Fire

Remove the second and fourth wires down on the Kiln Bead Tree or Bead Rack. Hang the pendants on the top and third wires – usually 2 pendants will fit on either side of the wire. Be sure that none of the pendants are touching each other or the bead tree. (I usually separate them after I put them in the kiln, otherwise they fall off between my workroom and my kiln.)

Glaze Fire according to the glaze manufacturer’s and kiln manufacturer’s instructions.

Evaluate

Hopefully, you will be pleased with a few pendants and want to wear them or give them as gifts. Attach 9mm or 10mm jump rings to these (see this video tutorial on jump rings).

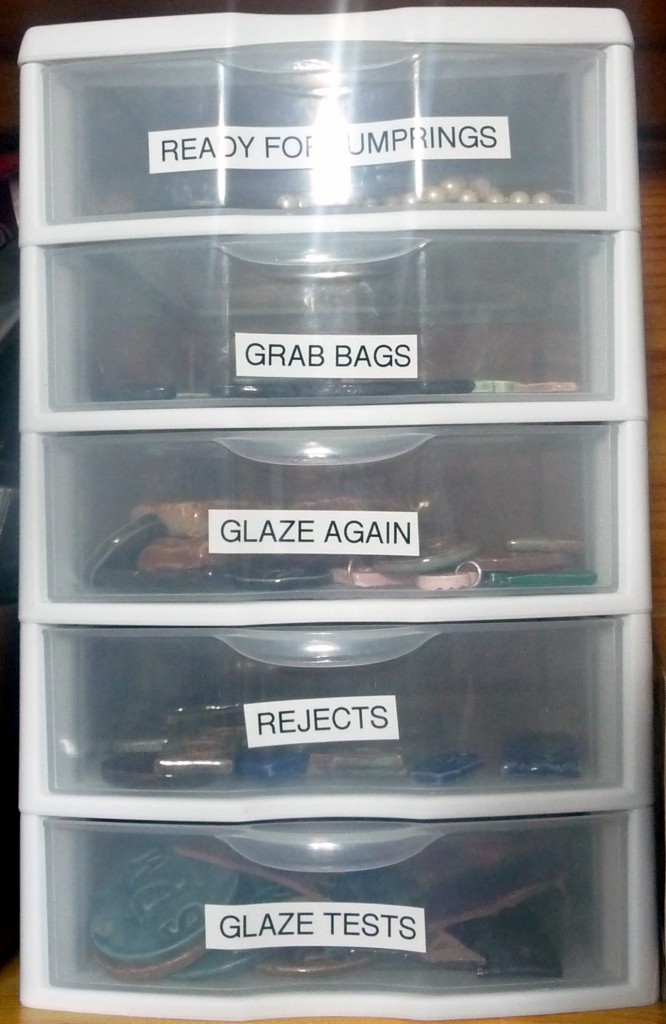

Don’t be discouraged if there are several that don’t meet your expectations. Over the years I have thrown out or given away to my mosaic-making friends more pendants than I have kept to sell or wear! I have a small box of 5 drawers, each labeled:

- “Ready for Jump Rings”- I am pleased with these and can sell, wear, or give as gifts

- “Grab Bags” – These are on the line – not bad enough to trash, but not good enough to sell individually. I put 4 – 8 of these in little attractive “grab bags” and sell them for $10 per bag at craft shows.

- “Glaze Again” – These are the pendants that may look perfect with a little more glaze. Sometimes glazing again works, sometimes not.

- “Rejects” – For my mosaic-making friends

- “Glaze Tests” – Good enough to show how a particular glaze looks on a particular clay. Be sure to label them.

I welcome any questions, comments or suggestions! Have fun and experiment with different clays, shapes, textures and glazes!

Copyright 2011 Kathryn Depew

Have you tried this project? Please comment below and leave your ideas and suggestions!

Disclosure: I was not compensated for this post. I am an affiliate of Amazon, and will receive a small commission if a link on this page is used to make a purchase.

Your work is wonderful.. Had health issues that took me away from doing clay but you have inspired me with your great ideas. I do both pottery and polymer so this is fabulous! Thanks!

You are welcome, Carol! Thank you for stopping by and for your encouraging words!

Thank you!!

You know how excited I am to have found you? Like Super!!!

Thank you for sharing how to make clay jewelry. This is exactly what I would love to do. I am looking for online or onsite clay jewelry classes. Do you offer any?

I am specifically wanting to learn more about how to make porcelain jewelry.

Am definitely going to start playing with clay!

Please keep in touch.

Thank you, Ana

I love it. Thanks for the great images— it makes understanding the process so much better 🙂

Love your clay pendants and buttons! They are beautiful? I’ll definitely visit often to see what you’re up to 🙂

Very nice! I have been wanting to make some clay pendants lately! Where do you find your pattern imprints?

Thanks for sharing such a wonderful site!

CN

Thank you! I’m glad you liked this. For patterns I use rubber stamps, buttons, shells, plaster stamps, leaves, just about anything that will leave a pattern in clay when pushed. 🙂 Thank you again!

Beautiful pendants Kathie – nicely explained. Thanks for sharing.

Got one question if you don’t mind – ‘what kind of high temperature wire do you use and where did yo get it from?’

Cheers 🙂

Hello, thank you for your question! I use the Kemper High-Temp wire. I bought it from a wholesale distributor, but also have found it on Amazon, BigCeramicStore.com and Clay-King.com. Hope this helps! Thank you for your compliments, hope you enjoy making the pendants!

Great tutorial. When you say you use a high fire clay, I am assuming you are referring to a Cone 5 or 6. Can you do this with low fire clay as well?

I generally do slip work but would love to try my hand at this.

Thanks!

Hi Charlie,

I’ve worked with low fire clay before, but not to make the pendants. However, I don’t see any reason why it wouldn’t work just as well as the Cone 5/6 high fire clay!

Thank you for your comment and your visit!

Kathie

Can you tell me what glazes you used on the oval blue in the example. i tried something similar with an oplescent glaze, but it was too flat and not enough depth, like a glimmer. thanks for the tutorial. this lesson has inspired me.

Hi Terri, Thank you for your comment! This is the Blue Rutile Glaze by Amaco on Speckled Buff clay by Laguna. You are welcome for the tutorial – so glad it helped you!

Hi Kathie,

What a article, directions and photos. I’ve been making pottery for several years, but beads for only a few months. I think of them as little snippets of a bigger picture. My beads have included small hole and larger hole for cording and no hole with high temp wire.

I have been less than satisfied with some of the glaze effects. All of the beads are high fired to cone 6 with our other pottery items. Could you tell me what method you are using to reglaze the pendants?

Thanks, Kathy – Tipsy Mermaid Art

Hi Kathy,

Thanks so much for your comment and your question! Reglazing sometimes helps, sometimes doesn’t. But often it is worth a try! Usually I just brush on a little more of the same glaze in the spot(s) where it is needed. I tried dipping my pendants but find better results when I brush on a coat at a time. Hope this helps! Thank you again!

Could you tell me how well the Kemper wire does in cone 6 firing? I see that the package says OK for cone 5.

Hi Terry,

Thank you for your question! I mostly fire to Cone 5, but have fired with the Kemper wire up to cone 6 occasionally, and it did fine for me. You might want to do a test run first though. Hope this helps!

Kathie

Love your input. I make all kind of stuff with modeling clay and when making beads or pendants I do it all in one shot. I make the item, let it dry. Glaze it and Fire it using Cone 04. They come out great!!! I sell my crafts in Old San Juan, Puerto Rico and my clients love my pieces….So save time and money…all you out there!!! Blessings.

Wow! Thanks , I’m going too try this !! 🙂

Great! Thank you for your comment, and have fun!

Thanks so much for this – I’m planning to make buttons in a class I’m taking and this is extremely helpful. I love your work!

These are really stunning. Your step by step instructions are really helpful to a beginner like myself. Very much inspired. Thanks for sharing

You are welcome, hope you enjoy creating your own pendants! Thank you for your comment!

Your work is amazing! And I was wondering if you could help me out. My Mom had this kiln fired pendant made for her by my dad years back but unfortunately it broke apart about 6 months ago, and she was devastated. Would there be any chance of me being able to send you a picture of the pieces put together, and you could perhaps try to recreate it? Thanks Carenza:)

Hi Carenza,

Thank you for your comment and question! I apologize it took me so long to get back to you. I’m not working in clay right now (chasing my preschooler around instead!) I hope to get back to it in the near future. Hope you can find someone to help you! Thank you again,

Hi Kathie, great tutorial you have inspired me to give this a try! I have been searching for days for clay bead making and this is the only one I have really found is there a book or e-course you would recommend? (while I wait for supplies to arrive) thank you for the inspiration! jo

Hi Joanne, I apologize for the delay in my reply! I learned how to make my pendants through a tile-making course at a local pottery shop, and through lots of trial and error. I haven’t found a book on making ceramic beads but I’m sure they are out there. You might try looking at polymer clay bead and pendant books for inspiration. There are also lots of artists on Etsy making clay pendants and beads, you could look there for inspiration, too. Have fun!

This is a wonderful site, thank you, you have given me so much inspiration today, and have answered so many questions that have been bubbling away in my head. I’m off to try some of these techniques, who says you cannot teach an old dog new tricks!

Thanks so much, you are very encouraging! Come back soon!

Hi! Thank you for all the information!

Do you happen to know how necklaces made out of grey clay that needs to be kiln fired compared to necklaces out of polymer clay?

Hi Sharon, I’m so sorry for the delay in my reply! I have worked with polymer clay to make miniatures, but I haven’t made pendants out of this material. I have seen some lovely work at craft shows, though. They have a different look and feel. I would recommend doing an internet or Pinterest search for images, and decide what you like best. The advantage of the polymer clay of course is that you don’t need a kiln!

Kathie

A question for you: I own a Paragon SC2 kiln that I bought for making metal clay jewelry. I’ve never used it because the price of the metal clay went through the roof. But I’ve been thinking about ceramic buttons and jewelry…do you have any idea if my kiln would work for this? I don’t know a THING about firing or glazing ceramics. Started to take a class when I was an art student and I broke my arm so had to drop it. 🙁 All these years later, maybe I could do this!!

Thanks,

Jennifer

Hi Jennifer,

Thank you for your question! I apologize for the delay in my reply. Most of the pendants that I make are fired to ~ 1970 degrees (Cone 04) and then to Cone 06 and or Cone 5, depending on the glaze. I’m not familiar with the kiln you mentioned, but if it goes to these temperatures I would think you could use it for ceramics. You may want to go to the Paragon web site or call them to make sure. Hope this helps!

Kathie

BTW, I meant to start my question by saying I LOVE your work, and your site is really inspiring!

Jennifer

Thank you!

Hi Kathie, thank you for sharing this.. your work is beautiful. Could you share little bit about your kiln, size, brand, electric or gas etc.. and could you tell us how to select a kiln for home use.. i plan to start with something small but eventually make bigger clay pots.. please share your thoughts 🙂

thanks in advance

Hi Bilva, Thanks so much for your comment and questions! I have two Olympic Electric Kilns with Digital Controllers. They were recommended by a friend who has been firing porcelain for years. I have one that is 12″ x 9″ and one 8″ x 8″. They have worked very well for small wares and my pendants. I usually fire to Cone 5, but also to Cone 06, and both of these kilns have performed very well over the last several years. My husband had to replace the elements on the larger kiln once, and it was rather easy (he said). I keep these in my garage and I believe you need a 240V outlet for the 12×9 kiln. I would recommend considering one of these if you would like one for home use. (I have used other brands at the pottery studio I used to go to, but that was years ago and I don’t know much about them.)

Thanks again – I hope this helps! Please let me know how it turns out!

Kathie

My partner and I absolutely love your blog and find almost all of your

post’s to be just what I’m looking for. Does

one offer guest writers to write content to suit your needs?

I wouldn’t mind writing a post or elaborating on a few of the subjects you write concerning

here. Again, awesome website!

Thank you for your comment! Right now I am not looking for guest writers, but thank you for your kind offer!

Quick question: I am using the kind of clay you bake in your home oven (not polymer clay, regular terra cotta brown clay) to create pendants. Once baked, how would I prepare the “bisque” pieces for painting, especially to give them the “glazed” look? I am thinking of experimenting with Pebeo’s Fantasy solvent-based paints but want to make sure I prep the “bisque” properly.

Thank you!!

Hi Traci, this method sounds like fun; I’ve never used the oven-baked clay you mentioned. I’m so sorry for the delay, I just realized that you asked this back in November! If you have the time, please let me know what you figured out!

Hi just found this tutorial and love it! I was wondering what glazes you used on the 3rd photo from the top: the teardrop shaped pendant?

Hi! Thank you for your comment! It has been awhile since I made this pendant, but I am 99% sure the two glazes used are Coyote Cone 6 glazes. I believe the top is Red Gold (or it could be Shino). The bottom is probably Expresso Bean Shino. I really like the Coyote Shino glazes, they go together nicely if you like to glaze pieces with more than one glaze. Thanks again, hope this helps!

can you please suggest how i might glaze both sides of a small tile without a hole? can i glaze one side, fire it, then flip & fire again? i’ve seen it suggested to use a layer of silica sand on the kiln shelf – do you think i could glaze both sides & lay one on the sand? THANK YOU!!!!

Hi Chris, I’m so sorry I didn’t respond sooner. Obviously I’m way behind in responding to my blog comments – I apologize. I haven’t tried glazing both sides of a pendant without a hole. Would love to know the results of your tests. Thank you for your question!

A very interesting article full of info. I have been looking for wire I can use in a kiln and now have the answer. When I cut out my buttons or pendants I lay cling film over the top and then cut it gives it a soft rounded edge.

Hi, love this article. I make beads and pendants and usually fire them to 05/06. I’ve been out of it for a few years due to moving etc but am getting back into it and have a couple of questions. I want to make what they call a cuff bead or bracelet bar about 2 ” long by abut 1 to 2 inches wide and they will have a hole or 2 on each short side to connect to the rest of the bracelet. I see that some people are curving them and want to know if you have made them, how much of a curve do you give them and what do you use for the curve i.e. a soda can etc. I don’t want much of a curve just a slight curve to fit around your wrist and I want something that’s easy and fast to speed up the production line.

My other question is, why do you drill a hole in the pendant when they’re half dry? I usually make a hole when the’re still damp with one of my tools or a bamboo stick.

Thank you for your reply.

Hello Linda, I apologize for the delay in my response! Thank you for your comment! The bracelet idea is wonderful, I have never made one before. I would think curving them on a sofa can would work. I drill the hole when they are half dry because when I try to make the hole when they are wet I tend to distort the piece. I’d say just do what best works for you. 🙂

Hi, Kathie,

Your work is absolutely gorgeous! So much talent.

I’ve done lampworking for about 25 years, but old eyes with cataracts have caught up with me. I actually like the look of ceramic beads and pendants as much or more than lampworked beads, and am hoping that you might direct me toward a source of information for beginners in the art.

I notice that a previous commenter asked about firing temps, and am unsure if my ancient kiln will go to 1600 degrees.. I fear it might implode, truthfully. It has been 40 years since my last class in ceramics, but I vaguely remember “cones”. Is there a way to fire clay at temps around 1200 degrees?

Many thanks,

Cathy

Hello Catherine, I apologize for the delay in my response! Thank you for your comment! I believe there are some low-fire clays out there. I haven’t done much in ceramics for a few years since my daughter was born 7 years ago (I hope to get back into it very soon – she is almost old enough to learn the wheel!) My memory is a little rusty on resources. I would look for a studio or artist near you for classes, or perhaps in the library for books, and also an online search. It’s a lot of fun, I wish you well!

Kathie, thank you for such a great tutorial. I was wondering, if I make pendants with holes and put them on a bead tree for firing, do I have to take special precautions that there is no glaze inside the drilled hole? I am thinking that when one brushes glaze on some, of the glaze would make contact with the wire of the bead tree. Thank you so much! Susanne

Yes I usually scrape out the hole before firing if I accidentally got some in the hole while brushing on the glaze. Good point!

thx for this great tutorial! just one question left for me: how much cornstarch should or could I use? is there any limit? thank you!!

Hello, I apologize for the delay in my response! Use just enough cornstarch so the clay doesn’t stick to your board. Kind of like making roll-out cookies.

Would I have to buy a wire for this or could I just break down a metal coat hanger and use that. I don’t know much about doing this. I’m newish to pottery and don’t want the metal to melt in the kiln. But I’m also low on cash and don’t want to order special wire for this.

No, you need specialist high temperature wire which you can buy in metre lengths on online auction sites quite reasonably. Coathanger wire is way too soft and would melt and probably give off fumes.

Here is an idea: use a cocktail drink straw to make the hole on pendants…of course it depends on the width of the cord you will use. I usually use rat tail cords. I cut the straw into approx 2 in length and it becomes real easy to make holes. I also use regular straws and wide straws for anything that needs a hole!!! Easy!!

Thank you for your generosity in sharing knowledge !

Wonderful blog – beautiful work !

Thanks again !

I Katie this is a great post to learn and give it a try!

I just have a quick question to ask.. I want to take a hole really small or attach the metal part to the clay and fire them together. What kind of metal can I use?

Thank you and have a great day!

Thank you for your comment – so sorry it’s taken so long for me to reply! Hope you’ve found your answer before now! 🙂 You have to use high-temp wire. If you search on a ceramics supply site or even Amazon you should find it. Hope this helps!

Beautiful blog! I am in love with it! I work on bisque fired terracotta. ..recently tried painting acrylics on the jewelry. .even after many coats of paint and the varnish ( i use Atelier traditional gloss varnish),though they look pretty and all, at some point the paint peels off(doesn’t flake off but literally the layer comes off)..its sad to see that after all the hard work. .wondering if you could shed some light on what is happening?

A space to indulge!

Thank you!

Hello, I’m sorry I haven’t tried acrylics on clay before. It seems the clay and paint aren’t compatible. I’ve just used the fired-on glaze on clay. So sorry it took me so long to reply! Hope you’ve found a more helpful answer before now! 🙂

Thanks for the info! When you glaze fire, do you use kiln wash on your bead rack? Have you had problems with the glaze/pendant sticking to the wire?

Hi Holly,

No, I just use it on the shelves, but I may try it on the bead rack in the future. As long as I’m careful to scrape the glaze out of the holes, they don’t stick. Hope this helps! (So Sorry it took me so long to reply!)

I’ve never thought of doing anything like until I stumbled across this page. I believe I’m gonna have to give it a try. Your work is very elegant. Nice job. 👍🏻

What a lovely, generous page – thank you so much – I am new to clay and have been building larger objects but will certainly have a go at these beautiful ideas. Thank you again xx

Is there a way to polish the tempered wire after firing?

I’m not sure…good idea!

This was so incredibly helpful to me!! I make ceramics and am transitioning to jewelery making and was having a hard time finding the “right” answers to my questions. Thank You so much!!